Safety on Steel Building Erection Sites

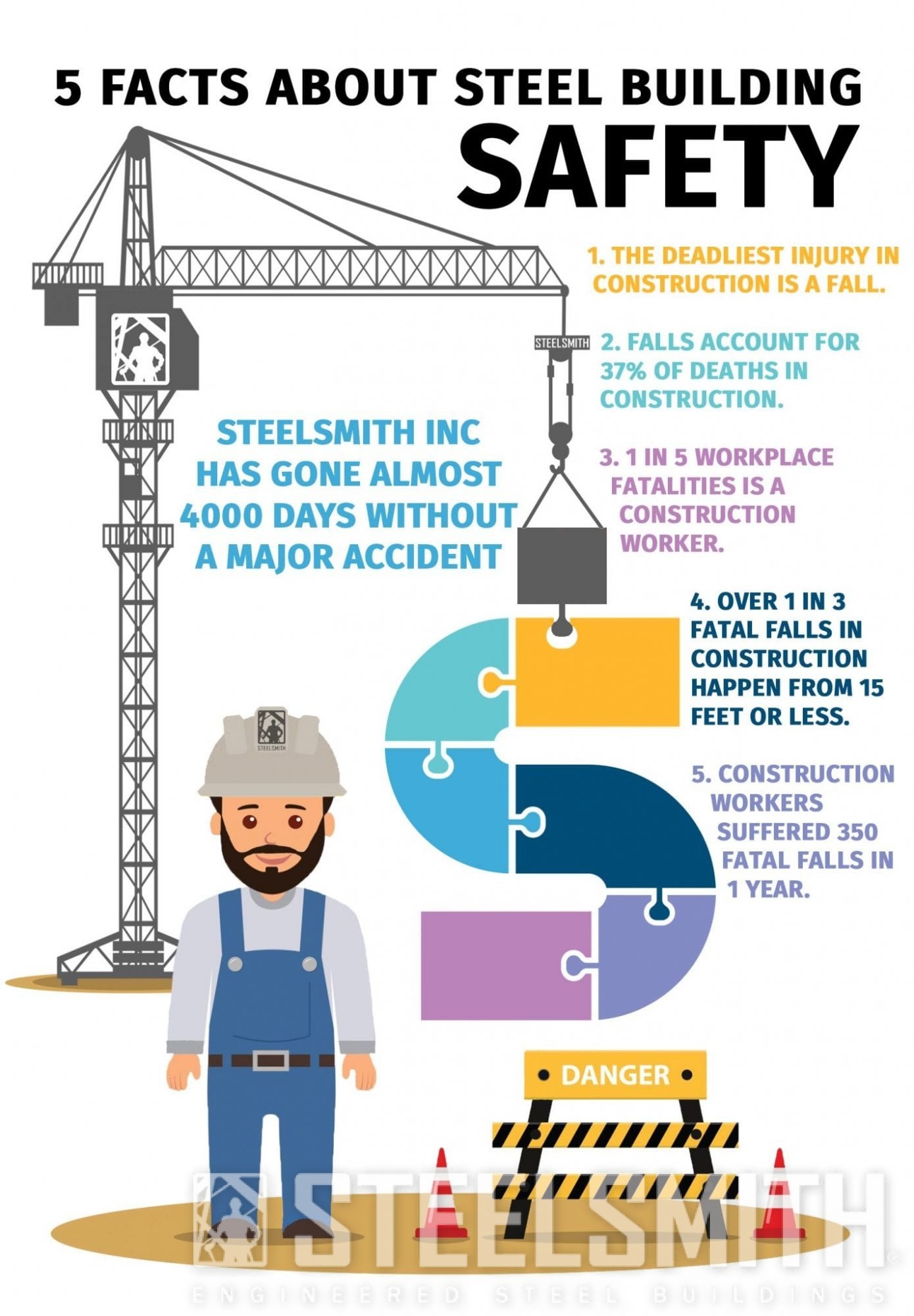

According to the Bureau of Labor Statistics one of every five workplace fatalities is a construction worker. Erecting steel buildings involves working with industrial machinery, heavy steel beams, and sometimes great heights. This combination of workplace factors can be very dangerous and even fatal when workplace safety is not a priority. Safe job sites are extremely important to us here at Steelsmith. We find it imperative that all of our erection crews and contractors take the steps needed to create a safe work environment.

Why should our customers care about our emphasis on job site safety?

We believe that safety in the workplace is of utmost importance for our steel building erectors, the contractors we work with, and for our clients as well. Our emphasis on safety not only demonstrates the protection we provide our employees and contractors, but it also highlights our professionalism and overall responsible disposition.

OSHA Guidelines

The guidelines set forth by OSHA must be followed by all steel building companies. As a customer, do not assume that all contractors follow these guidelines. Use the summary of information below and ask your potential steel building provider who will be playing these roles on your job site or which training your erectors have completed. As an educated buyer, you may even want to ask your potential steel building erectors for copies of their course certifications, especially if you are already questioning the company’s legitimacy or erection experience.

Competent Person(s)

For all jobs at Steelsmith, we have a ‘competent person’, which in its definition by OSHA, is a person at the job site who can identify any hazards associated with a specific operation. Usually, this person is the foreman on site. This individual is also authorized to take corrective measures to eliminate any hazards they identify. This individual is the person on site who’s responsible for assessing risks and preventing any injury from occurring.

OSHA 10 Hour Training for Construction

The guidelines set forth by OSHA must be followed by all steel building companies. As mentioned previously, as a customer, do not assume that all contractor follow these guidelines. Use the summary of information below and ask your potential steel building provider who will be playing these roles on your job site or which training your erectors have completed. As an educated buyer, you may even want to ask your potential steel building erectors for copies of their course certifications, especially if you are already questioning the company’s legitimacy or erection experience.

OSHA 30 Hour Training for Construction

The OSHA 30 Hour training course for construction is designed for foremen, supervisors, engineers, architects, and management on both commercial and residential construction sites. Some states, such as New York and Nevada require this certification for construction site supervisors. Many public or government projects also require OSHA 30 trained individuals. This course is ideal for steel erectors because the course includes a focus on steel erection, unlike the 10 hour training which does not. The course covers 26 lessons including subjects like fall protection, crane safety, fire safety, and concrete and masonry.

Steelsmith Workplace Safety

Steelsmith emphasizes workplace safety by abiding to all current OSHA regulations, and completing ongoing safety training. The text below is taken directly from the Steelsmith Safety Program, which was written by Steelsmith President, Donald Gilmore:

“It is our policy to provide a work environment that is inherently safe. The safety and health of our employees is of primary importance as they are our most important resource. Safety takes a commitment from all personnel within our organization. We have developed a comprehensive safety program that addresses our specific safety concerns and provides guidance for the performance of our individual job tasks within the framework of appropriate Occupational Safety & Health Administration (OSHA) standards.”

Our safety manual contains numerous prevention plans, as well as detailed policies and procedures we have developed over many years of building steel buildings. Here is a list of all of the topics covered in our safety manual:

- Accident/Injury Prevention

- Safety Program Administrator

- Employee Involvement

- Housekeeping

- Emergency Action Plan

- Emergency Medical Response

- Fire Prevention Plan

- Portable Fire Extinguishers

- Fire Protection

- First Aid & First Aid Kits

- Sanitation

- Lifting, Pushing & Pulling

- Slips, Trips & Falls

- Drugs And Alcohol

- Smoking

- Accident Investigation

- Postings

- Record Keeping: Injuries & Illnesses

- Incidence Rate

- Safety Meetings

- Enforcement

- Schedule Of Enforcement Actions

The amount of detail and thought put into all of the plans and policies regarding the topics listed above are very extensive and thorough. For example, the information below was pulled directly from our ‘Housekeeping’ topic in the safety manual:

Housekeeping? On a job site? What’s that all about? It’s about safety! Employees are to maintain a neat and orderly work area as far as practical. Housekeeping and general cleanliness have a direct effect on safety and health. Proper housekeeping can prevent slips and falls, allow easy egress in the event of an emergency, prevent falling object injuries, and enhance fire safety. Below listed are general housekeeping rules:

- walking/working surfaces shall be kept clean and dry.

- do not allow construction debris to accumulate.

- stored materials will be neatly stacked at the job site.

- containers, when not in use, will be sealed.

- no objects will be left unattended on stairways.

- entrances and exits will be properly marked and not blocked.

- tools shall be properly cleaned and put away after use.

Our thorough attention to detail for various tasks, specific requirements, and situations is what sets our team apart from other steel building companies. Not only do we follow the OSHA Guidelines as required by law, but we make safety an integral part of our workplace culture, engraving it into our employees to decrease the possibility of accidents on all of our job sites. Steelsmith has all of the necessary insurance coverage for our services including the following:

- Commercial general liability

- Automobile liability

- Umbrella liability

- Workers compensation and employer’s liability

Compliance to Public Job Specifications Example

Currently, we are working on a project in Massachusetts for the Army Corp of Engineers. Some public jobs, like this one, require that we work with a safety manager. Our team is adept to working with outside managers and meeting requirements for our customers to include completing an Activity Hazard Analysis. We have no problem completing any steps needed to become best suited for a job. Like many of the states we erect buildings in, Massachusetts has state-specific safety requirements e. For example, Massachusetts requires a Massachusetts hoisting license, which is required above and beyond the typical forklift certification, should materials be lifted higher than 10’ off the ground or >500lbs. We take responsibility as a construction company, with a national footprint, that we understand and comply with each state’s safety requirements. Steel building erection can be safe when the crews are aware of the risks involved and have completed proper training. We are proud to say that no Steelsmith employee or contractor has suffered any serious injury or fatality while on any of our job sites. Our safety precautions have resulted in a safe work environment for our erection crews, and on-schedule construction timelines for our customers.

Ready to get a quote for your steel building project from a steel building company that makes safety on the job site a priority? Submit your quote now. Or, if you aren’t quite ready to take that step, take a look at some of our job sites and completed projects by heading over to the Steelsmith Project Gallery.